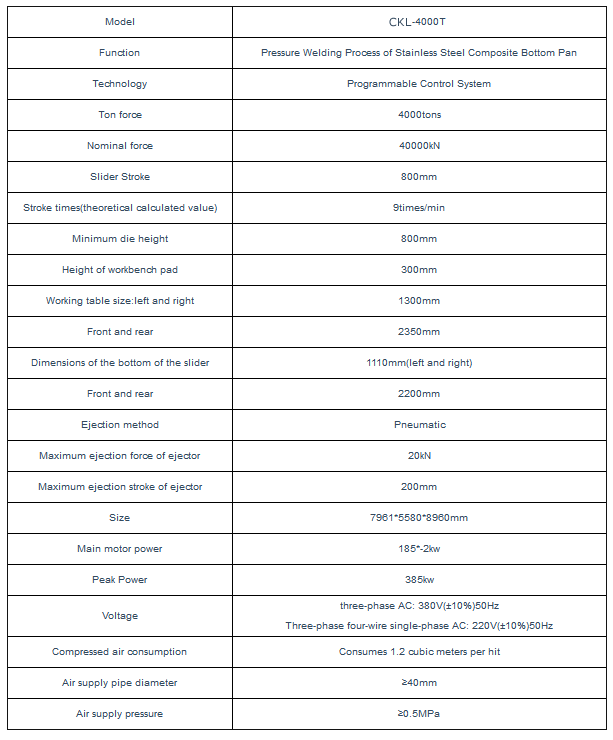

Press Machine Process of Stainless Steel Composite Bottom Pan

Item No. - CKL 019

Press Machine can used for pressure welding process of stainless steel composite bottom pan. It belongs to a traditional structural form of the screw press, and its main feature is that the flywheel is driven by a friction mechanism.

Specifications

Advantage

- Frame: The frame of the J54-4000 40000KN double disc friction press

requires sufficient strength and rigidity. A combined prestressed frame

structure is adopted. There are positioning rings between the base, left

and right columns, and beams for positioning, and four pull rods are

electrically heated and pre-tightened to form a closed frame. Left and

right support arms are installed at both ends of the upper part, which

is convenient for installing the transmission device.

- Transmission control system: The transmission is driven by double

motors. There are two control cylinders installed at both ends of the

transmission shaft, through which the air is fed into the cylinders to

push the piston to move left and right, so that the left and right

friction discs are alternately pressed against the flywheel, so that the

flywheel drives the slider to move up and down, and the forging is

completed, blow.

- Flywheel: The press adopts an overloaded slipping flywheel. When

overloaded, there will be relative sliding between the wheel body and

the wheel rim to play a role of safety insurance.

- The body of the slider is made of high-quality cast steel. The lower

end of the screw in the slider is equipped with a nut. After the nut is

tightened, a round pin is driven in to prevent loosening and falling

out. The slider guide adopts a long X-shaped guide rail, which improves

the guiding accuracy and enhances the anti eccentric load capacity of

the product. The gap between the slider and the rack guide rail can be

adjusted by means of adjusting the inclined iron.

- Protection platform: This machine is equipped with a safety

protection platform, which is the installation basis of the braking

device. It is welded by channel steel and angle steel. There is also a

rat cage ladder for the upper and lower platforms. It is convenient for

the installation and maintenance of transmission control.

- Braking system: The braking consists of two identical sets of braking

devices, which is symmetrically installed on the platform. The upper

part is tensioned by a tie rod, and the lower part is fixed on the

platform by screws.

- There are set screws on the platform to prevent the base from moving.

When braking, the piston rod chamber of the cylinder is exhausted. When

the rodless chamber is inhaled, under the joint action of spring force

and compressed air, the piston rod pushes the brake plate through the

shaft to press the outer edge of the flywheel, so as to achieve the

purpose of braking.

- Balance cylinder: The slider balance device is composed of two

balance cylinders, which is symmetrically distributed on the front and

back of the machine beam, and are used to balance part of the weight of

the motion system, avoiding the sudden drop of the slider, making the

slider move smoothly when it goes down, and is conducive to Slider

return.

- Ejection: Pneumatic double ejector rod structure is adopted, the

ejection force is 20kN, and the ejection stroke is 200mm.

- Air pipeline system: The air pipeline system is compressed air, which

is used to provide power to the transmission control, brake opening and

slider balance device. The pneumatic system is composed of an air

storage tank, a reversing valve, a pressure reducing valve, a

lubricator, safety valve etc.

- Lubrication: The equipment adopts centralized automatic lubrication

and decentralized manual lubrication. The four guide rails and the screw

pairs of the main lubrication points use an electric pump and an

automatic oil separator to automatically inject lubricating oil for

lubrication. The cylinder is lubricated by automatic oil spraying with a

lubricator installed in the air pipeline, and all other places that need

to be lubricated are lubricated with oil guns or grease cups.

- Foundation: The buyer invites a qualified civil engineering design

institute according to the installation foundation drawing provided by

the seller, and organizes the civil engineering construction after

converting the design into construction drawings according to the local

soil conditions. The thickness of the foundation cement pouring layer

should be determined by the user after exploration according to the soil

quality of the workshop. The foundation should have a waterproof layer

to prevent groundwater from seeping into the pit.

- Electric control system: It consists of a strong electric drive part

and a PLC (OMRON) control part. The control circuit is reasonable, the

movement is reliable, and it is easy to use. The main motor adopts

star-delta starting mode, which reduces the impact of starting current.